Additive Manufacturing for Biomedical Systems

We aim at enhancing the development process of ventricular assist devices with additive manufacturing (AM). It is a general belief, that AM can pave the way for a more efficient product development and new, innovative products. AM gives the opportunity to rethink methods of product design and provides a bridge towards radical solutions. This is particularly true for the development of biomedical devices where the specific benefits of AM appear to be specially effective.

The qualification or the set of required properties of a 3D printed part is very specific not only to the kind of final application but also to specific sub-functions that a prototype might be tested for. To promote the use of AM technologies in the development and application of ventricular assist devices, both the practical and technical implications have to be understood. Feasible areas of application have to be identified and a suitable AM process has to be selected, where necessary improved or even developed and lastly validated for a specific application on a case-by-case basis.

Case: Magnet Printing

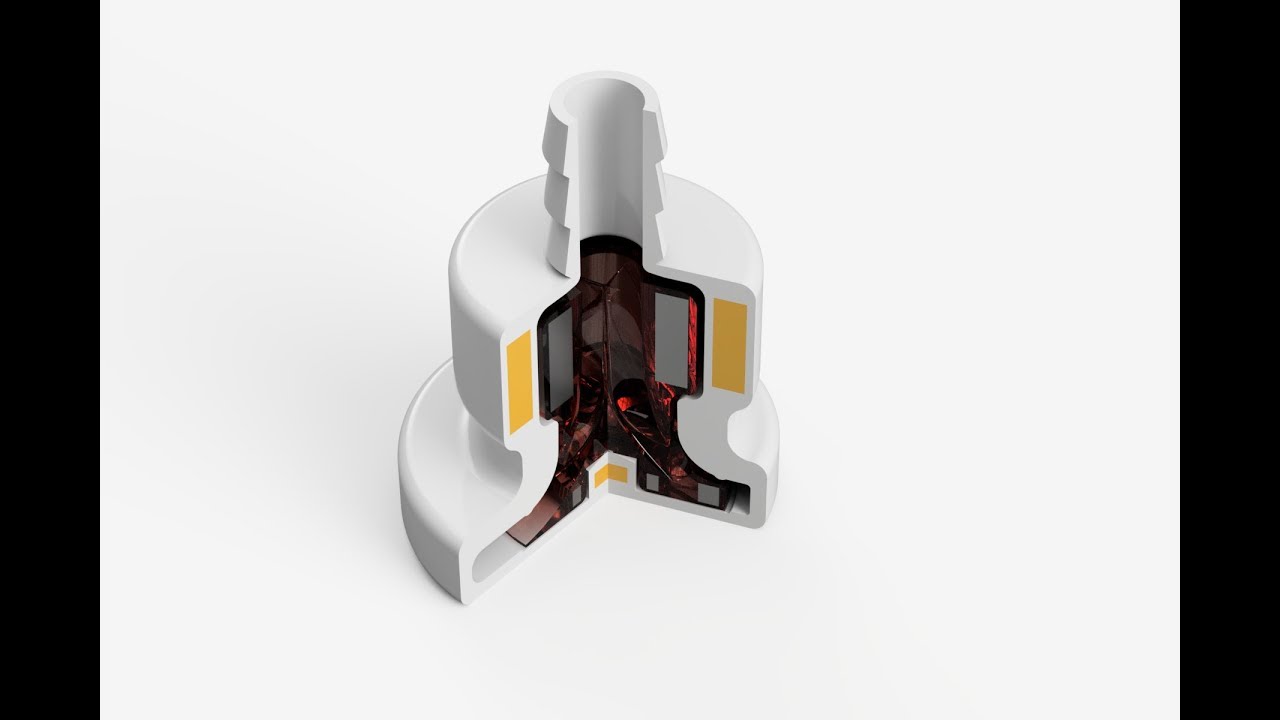

Magnets are an often critical component in MCS devices. The design of magnets is currently limited by the possibilities of conventional manufacturing methods. Additionally, complicated optimized shapes are likely to be avoided due to high manufacturing costs and long lead times. Therefore, we developed a flexible magnetic compound for the production of filaments for fused deposition modelling. It allows to all-in-one print functional assemblies with integrated magnets, such as blood pump prototypes.

This project is embedded in the Zurich Heart project.