Deep learning based smart camera applications in manual manufacturing

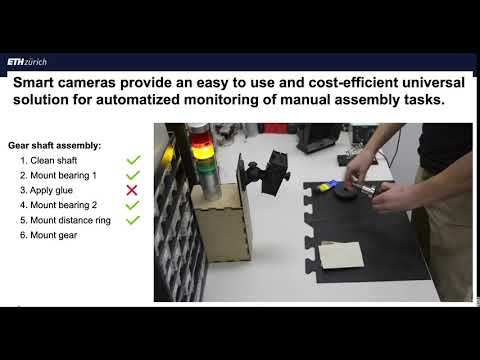

Smart cameras offer great potential as universal sensors for worker support during manual manufacturing tasks. The use of deep learning thereby accelerates the creation process of models which translate images into information. However, the application of deep learning in manual manufacturing also leads to specific challenges which we focus to overcome in our research.

Deep learning based assembly step detection for manual assembly tasks

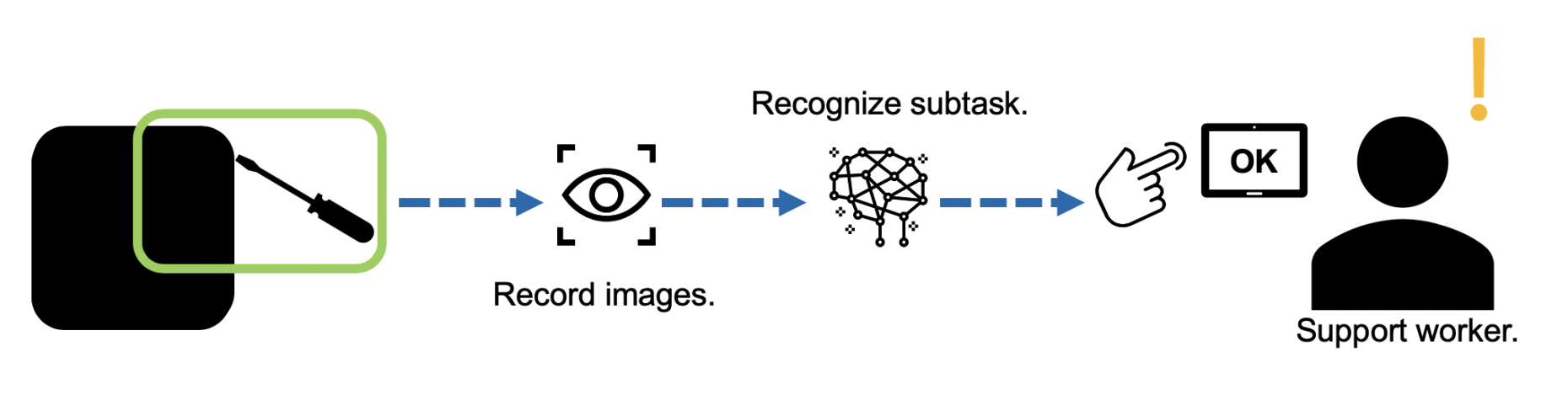

Manual assembly tasks become more and more complex with increasing automation and product variability. Smart worker support systems can therein help to ensure process quality and reduce worker’s stress load.

We are researching the opportunities and challenges of deep learning based smart camera systems to detect manual assembly tasks and provide feedback to workers about upcoming, realized or missed tasks. For this, a first evaluation was realized together with Sauter, Bachmann AG. Several support applications are to be realized in an Innosuisse project together with Huber+Suhner AG and Bossard AG.

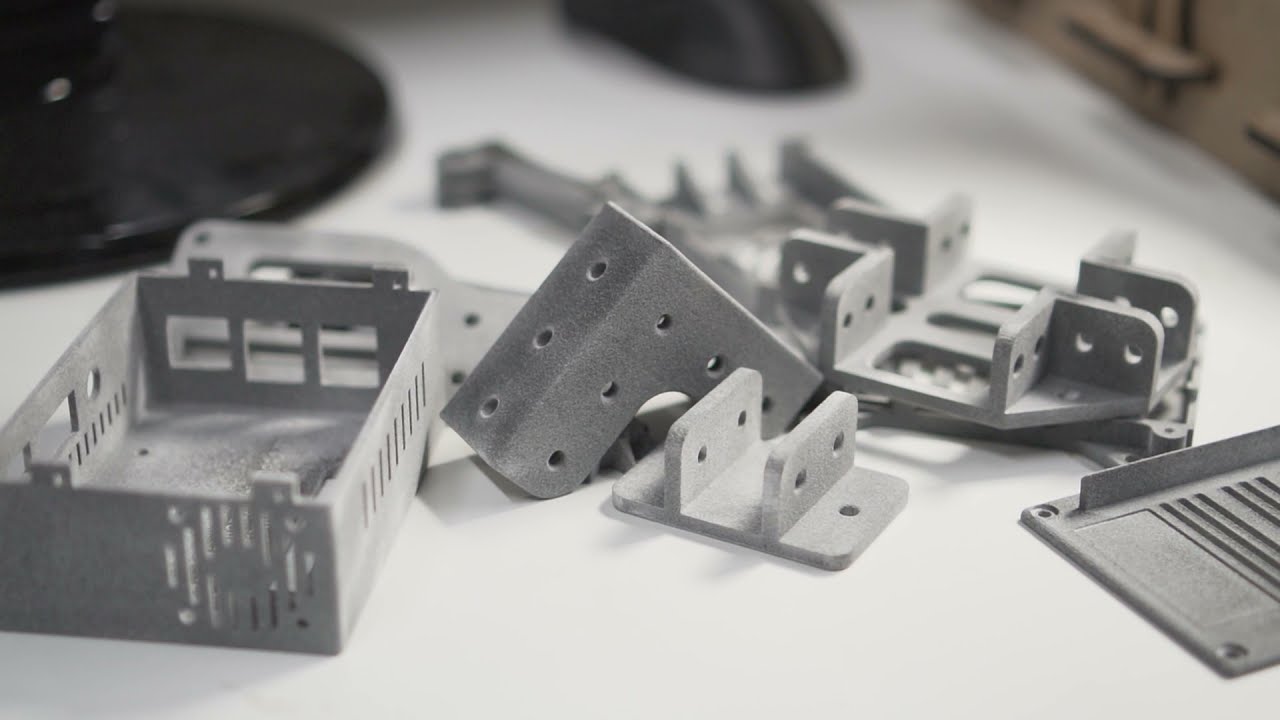

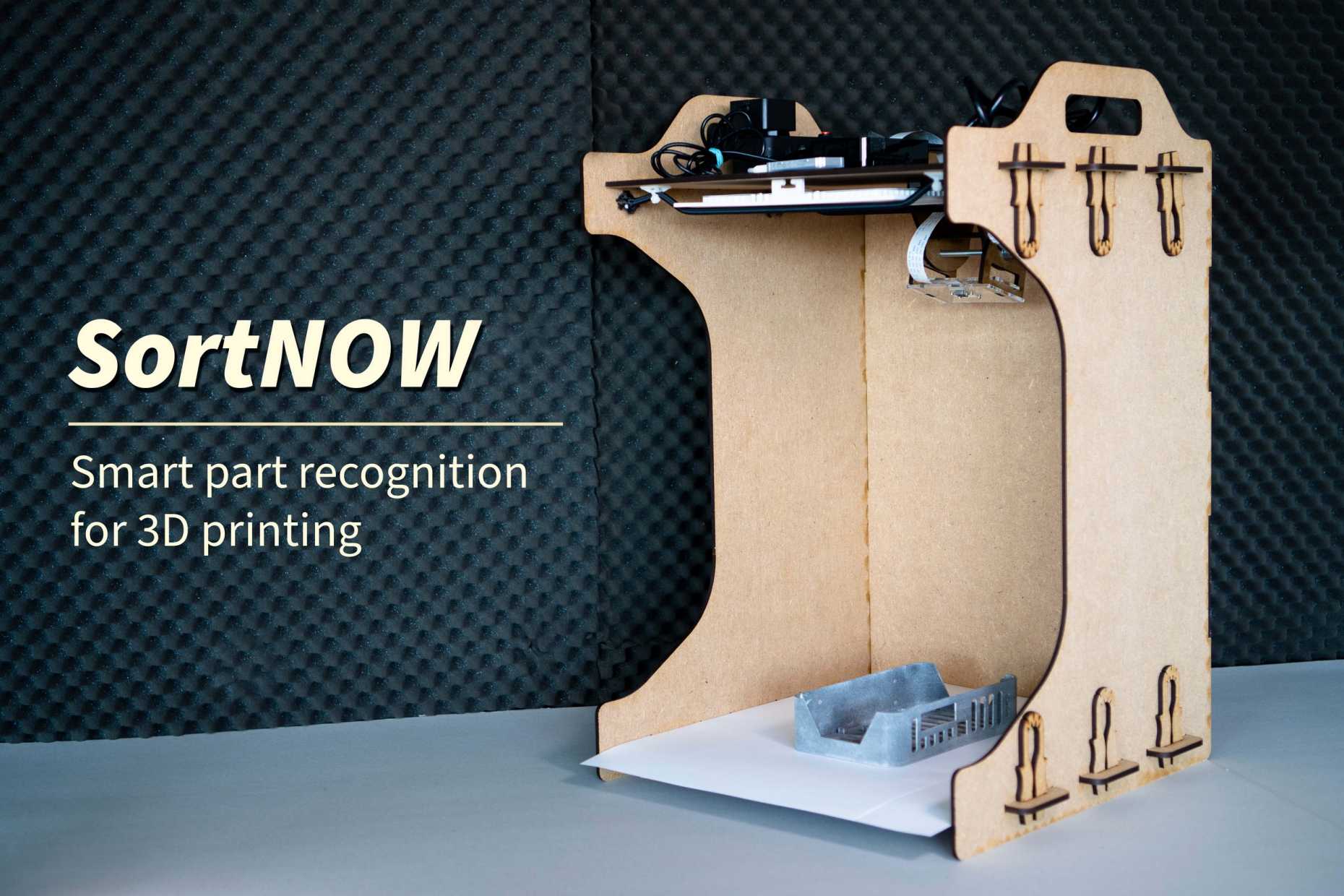

Automated generation of training data for deep learning based on digital 3D models

Training data generation presents a bottleneck in deep learning. This bottleneck can be overcome by the creation of training data based on digital 3D models. As a use case, powder bed fusion printing, an additive manufacturing technology, was identified. The process includes a manual part sorting step that prevents full automation of the fabrication process. Using the CAD models required for fabrication, virtual training data is created. This virtual training data is then used to train an image classification model, run on a simple smart camera system. Using this classifier, the system allows for the automated identification of fabricated parts. Based on the part identity, workers can be provided with all information for further processing, for example post processing instructions or other order details.

A first proof of concept was validated together with Wyss Zurich at their Multi Jet Fusion facility.